Robotic Boxing

Description

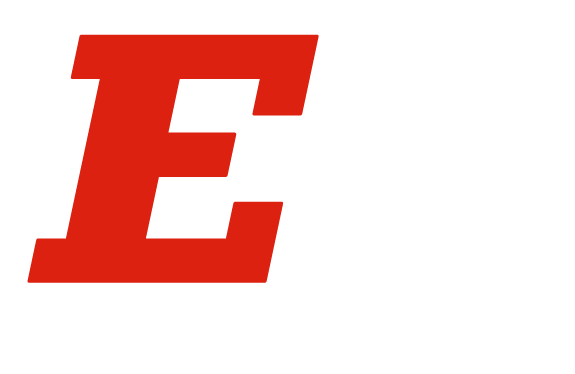

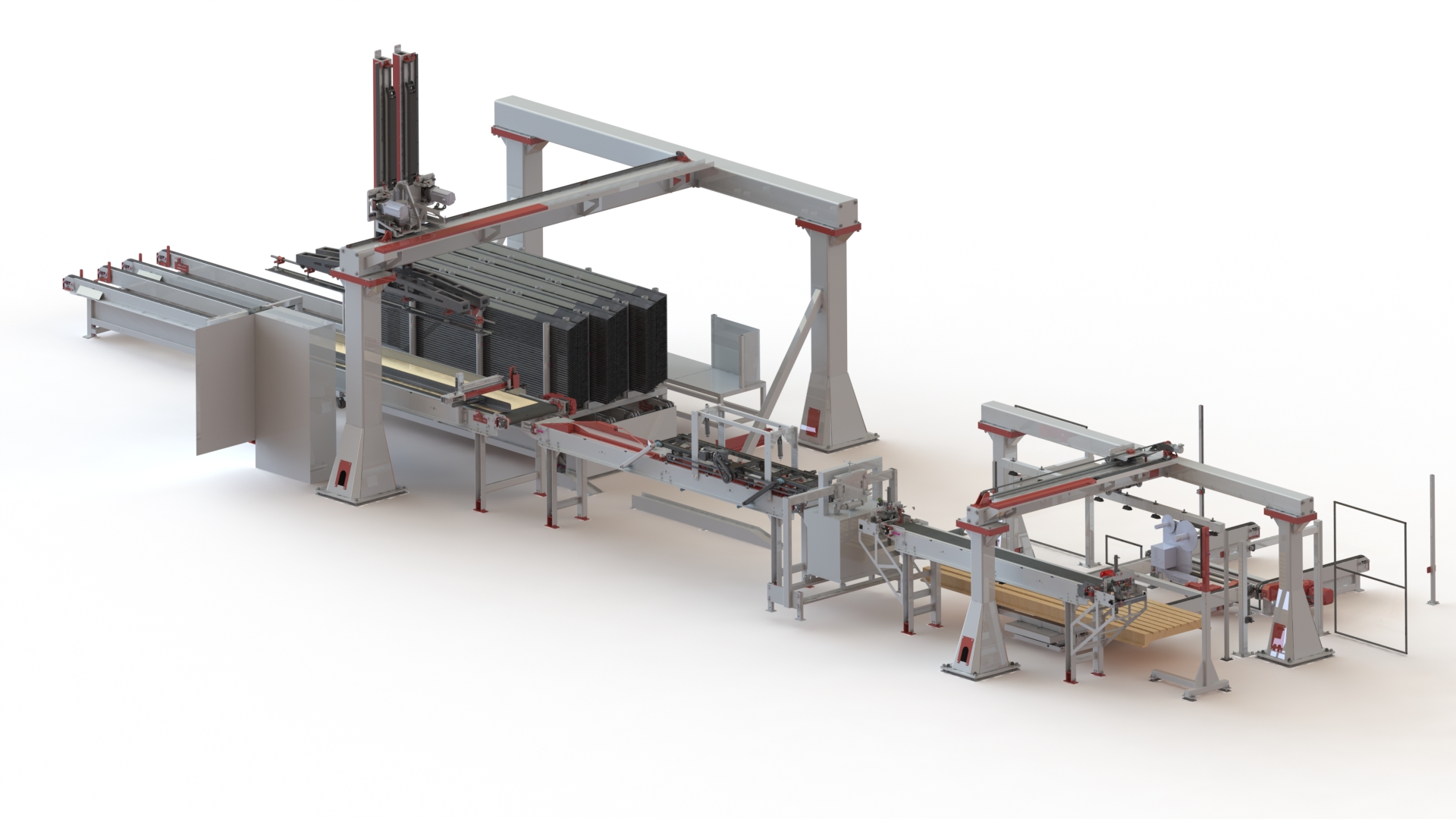

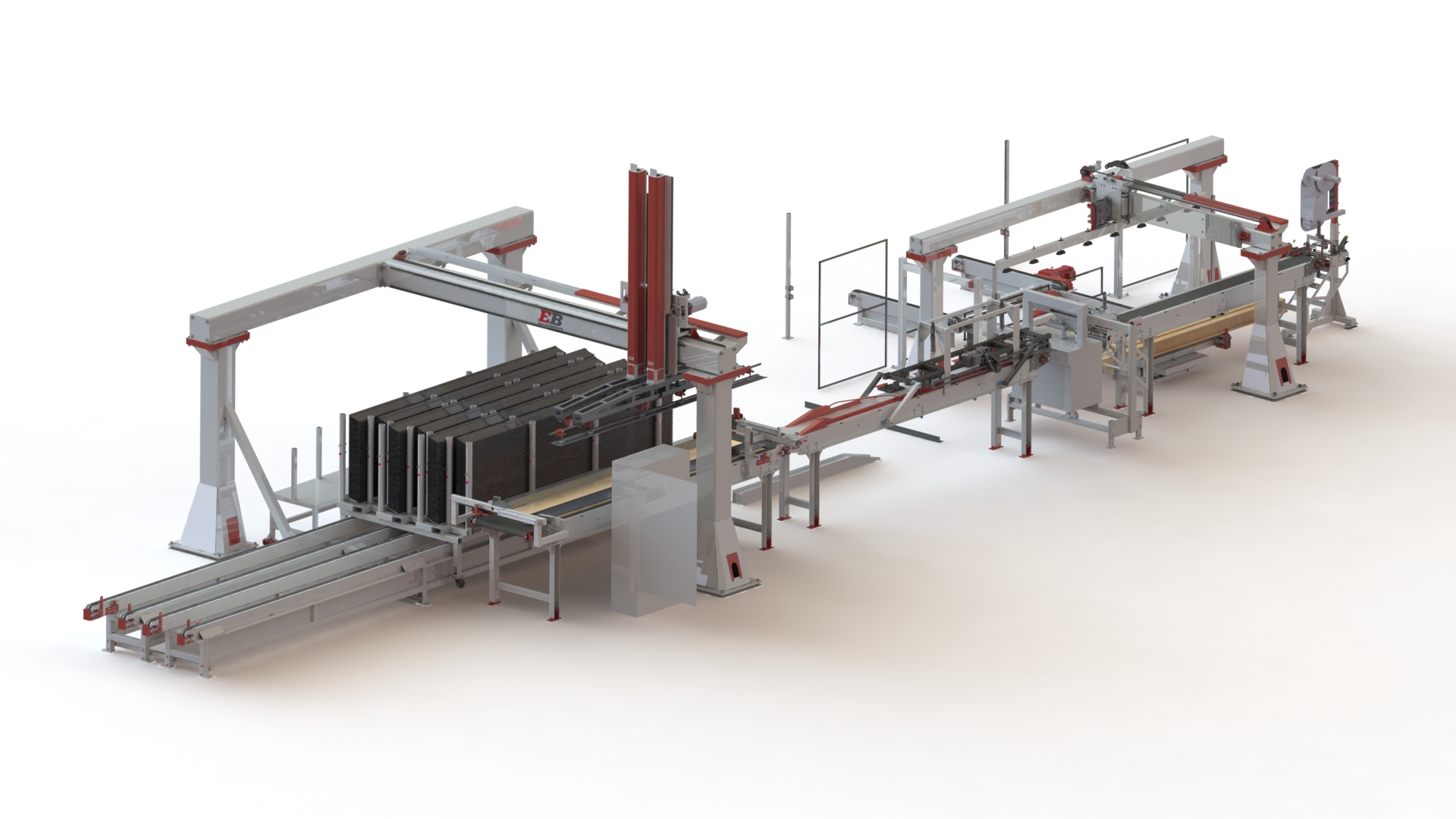

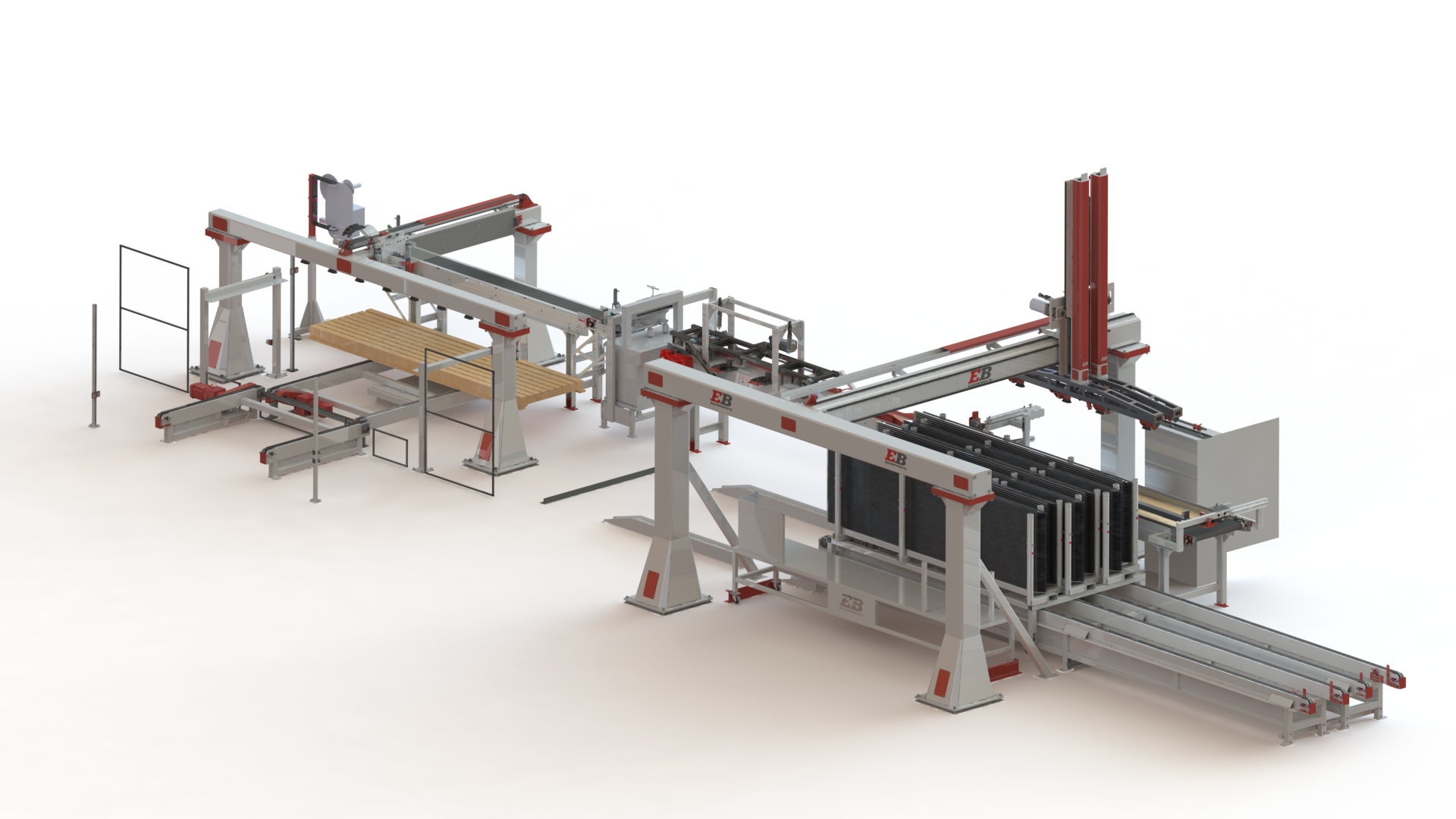

Automated system with a robot that places an unformed cardboard box on a conveyor to receive a precise quantity of pieces in order (front and back). The box is then transferred to the palletizing area where it is formed. During closure, nylon straps are applied, and the ends are glued.

A second robot handles the palletizing. Once the order is complete, the system automatically moves it to an exit conveyor to be picked up by a forklift.

The solution includes a gantry robot for handling profiles, a boxing system, and an automated palletizing system.

The protection system is composed of mesh and light curtains.

Standard Spécifications

- For components up to 5 m in length x 1 m in width

- Lifting capacity up to 250 kg

- Execution speed with a rate of up to one piece every 6 seconds

- Stacking precision based on the chosen options

- Non-standard capacities offered

Advantages

- Easy integration

- Solve the labor shortage issue

- Increase production

- Improve the quality of manufactured products

- Enhance safety to eliminate accidents

- Flexible solution

- Adapted to Industry 4.0

- Turnkey project available

Options

- Interconnection with your existing system

- Automatic alignment

- Measurement system

- Automated quality control

- Turning system (front and back)