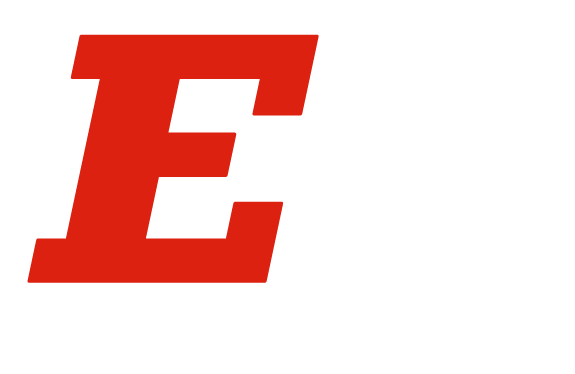

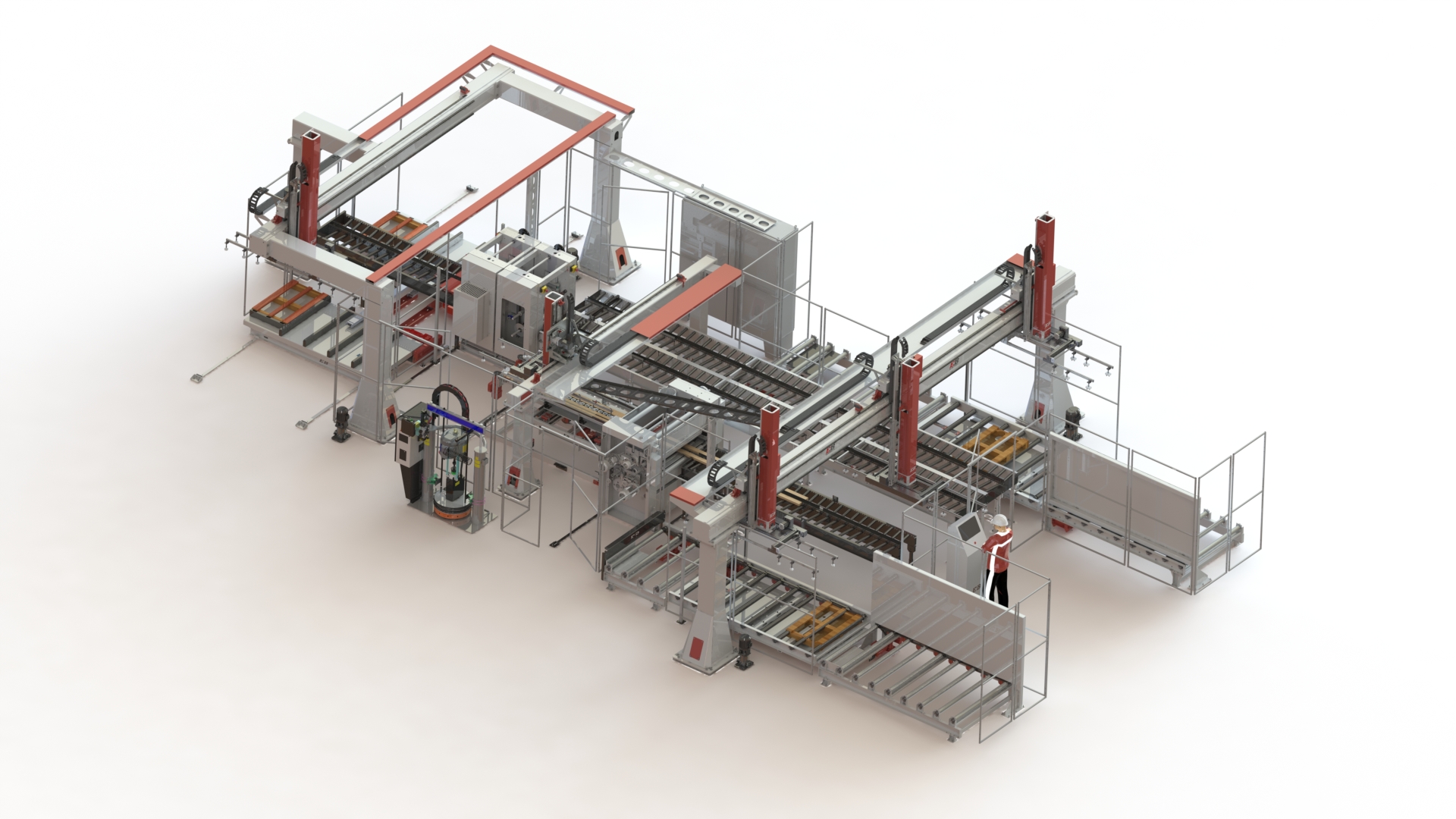

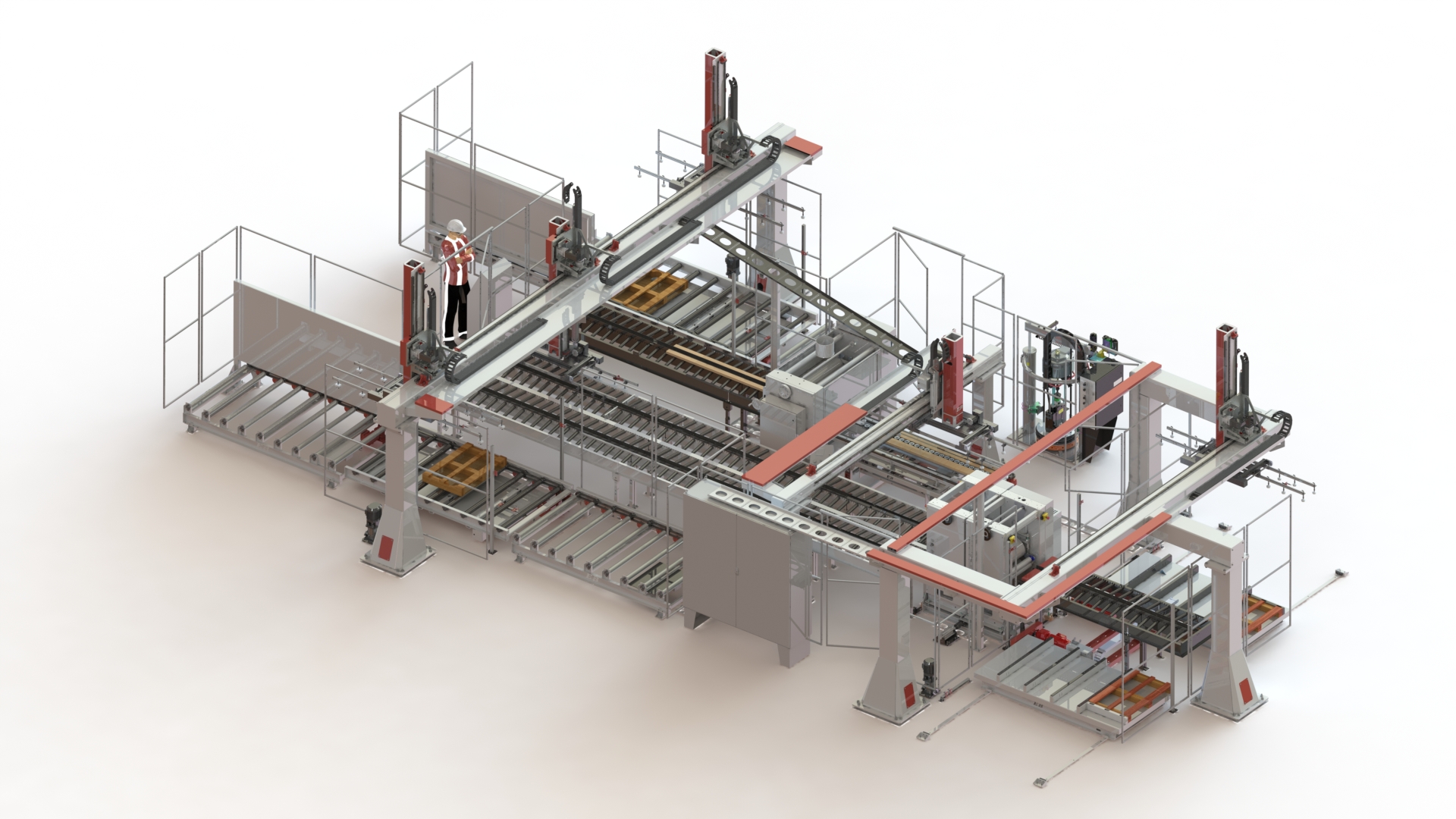

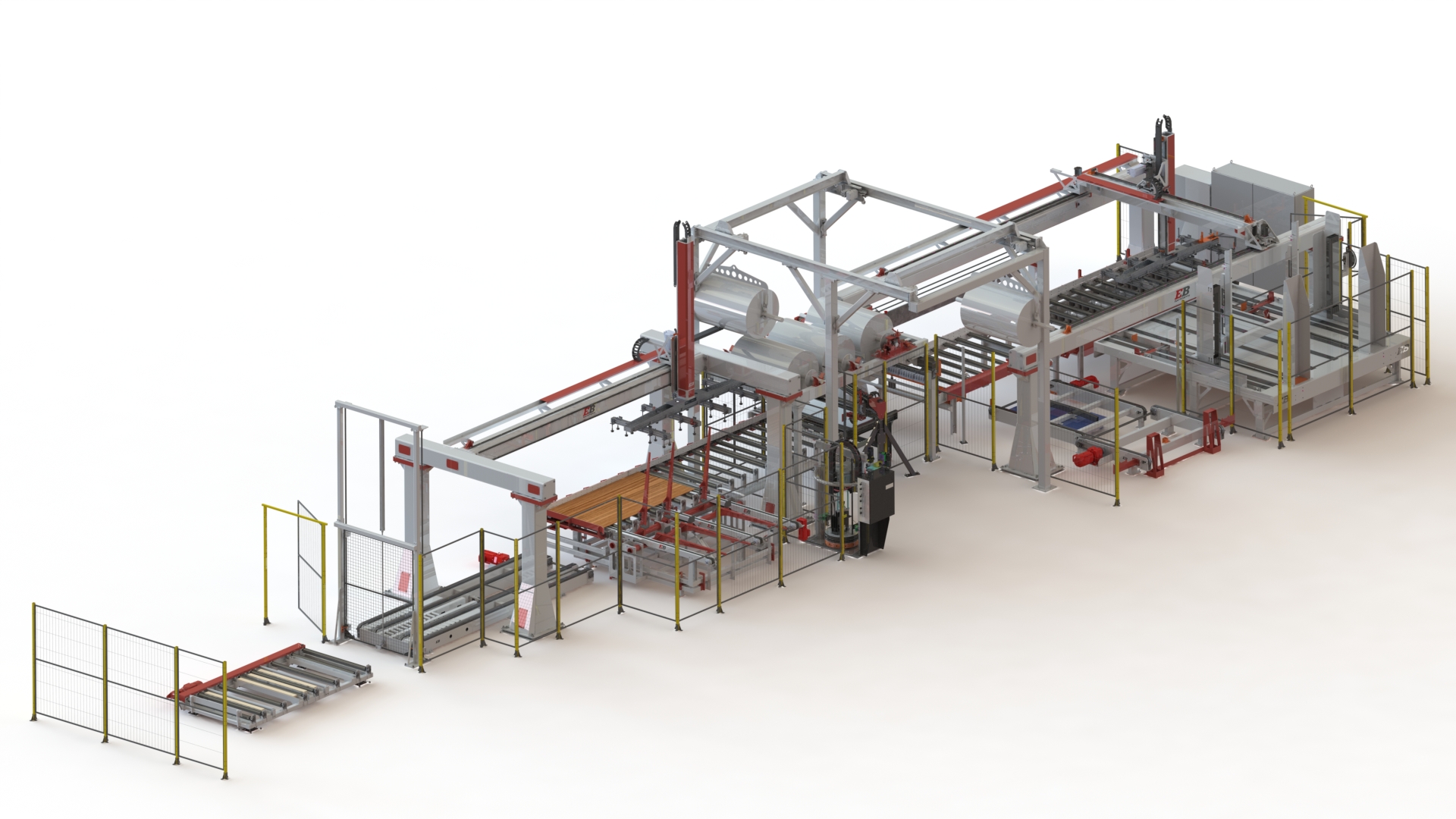

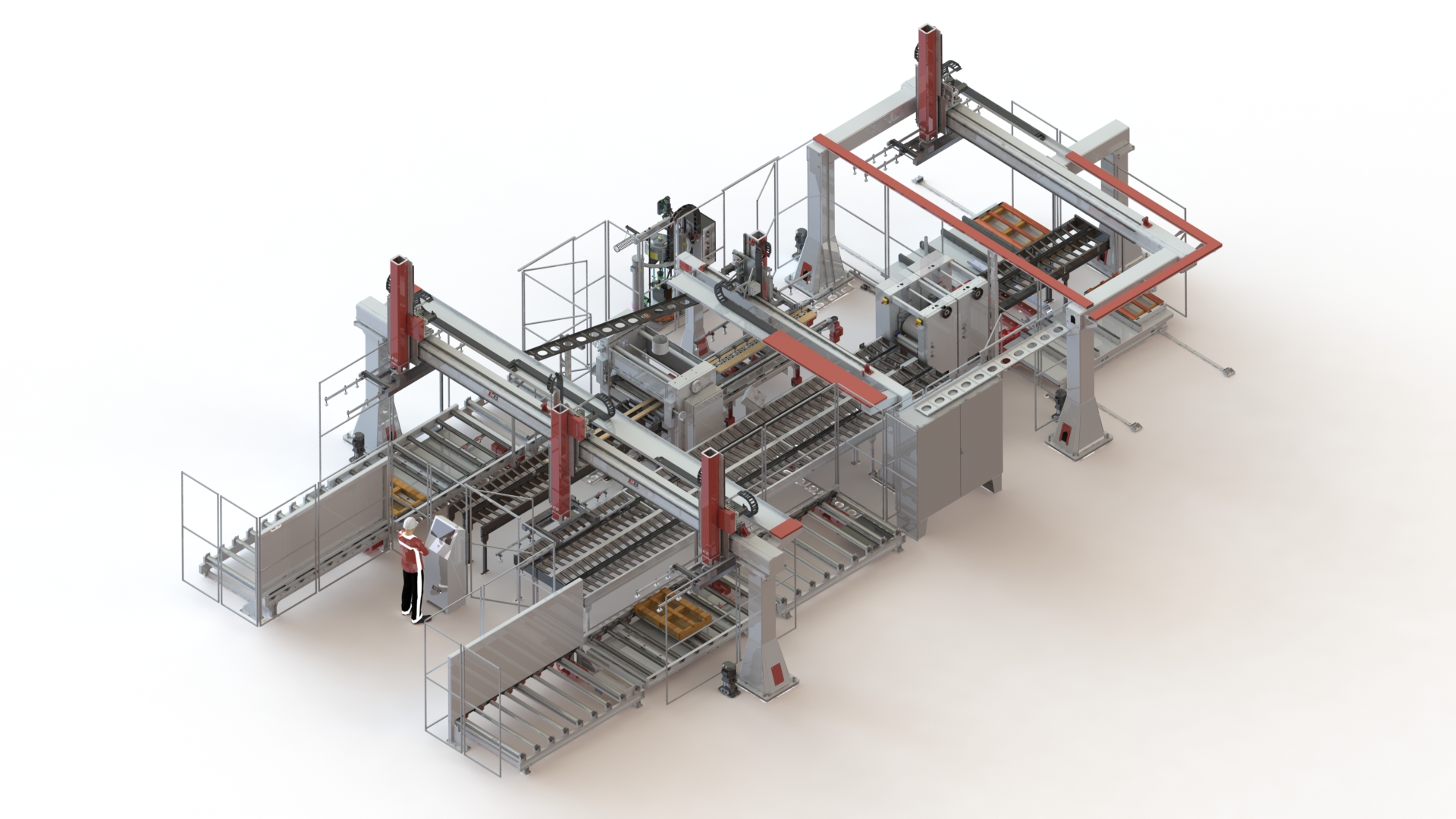

Lamination Line

Description

This cell can assemble various components such as bonding multiple panels and applying a film if needed.

The system is powered by one or more robots that perform numerous automated tasks:

- Apply glue and film according to recorded recipes

- Assemble the components

- Pass the pieces through a press roller

- Cut moving film at the joint between two panels

Palletizing is done by another robot that automatically moves to the output conveyor before being taken over by a forklift.

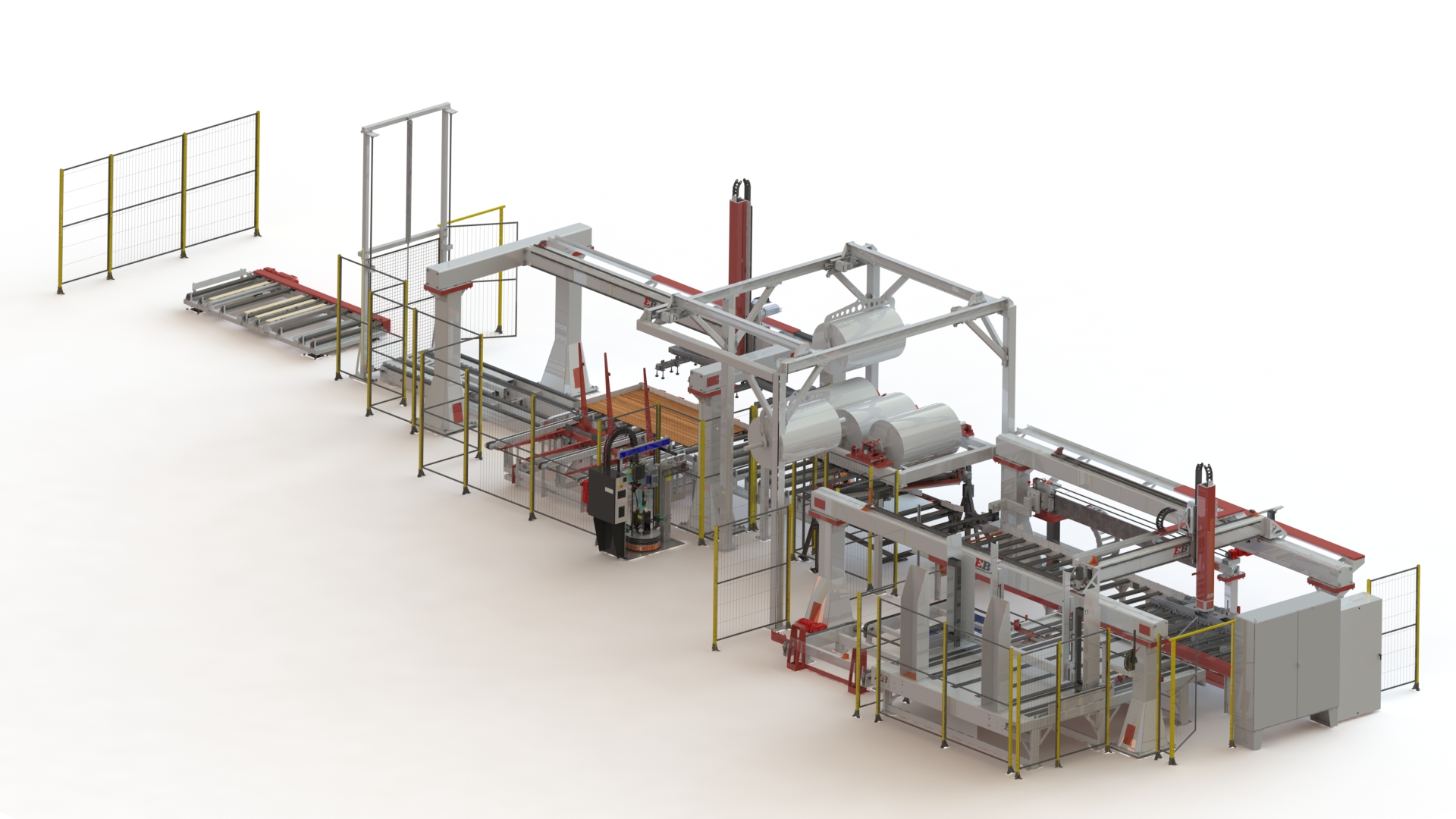

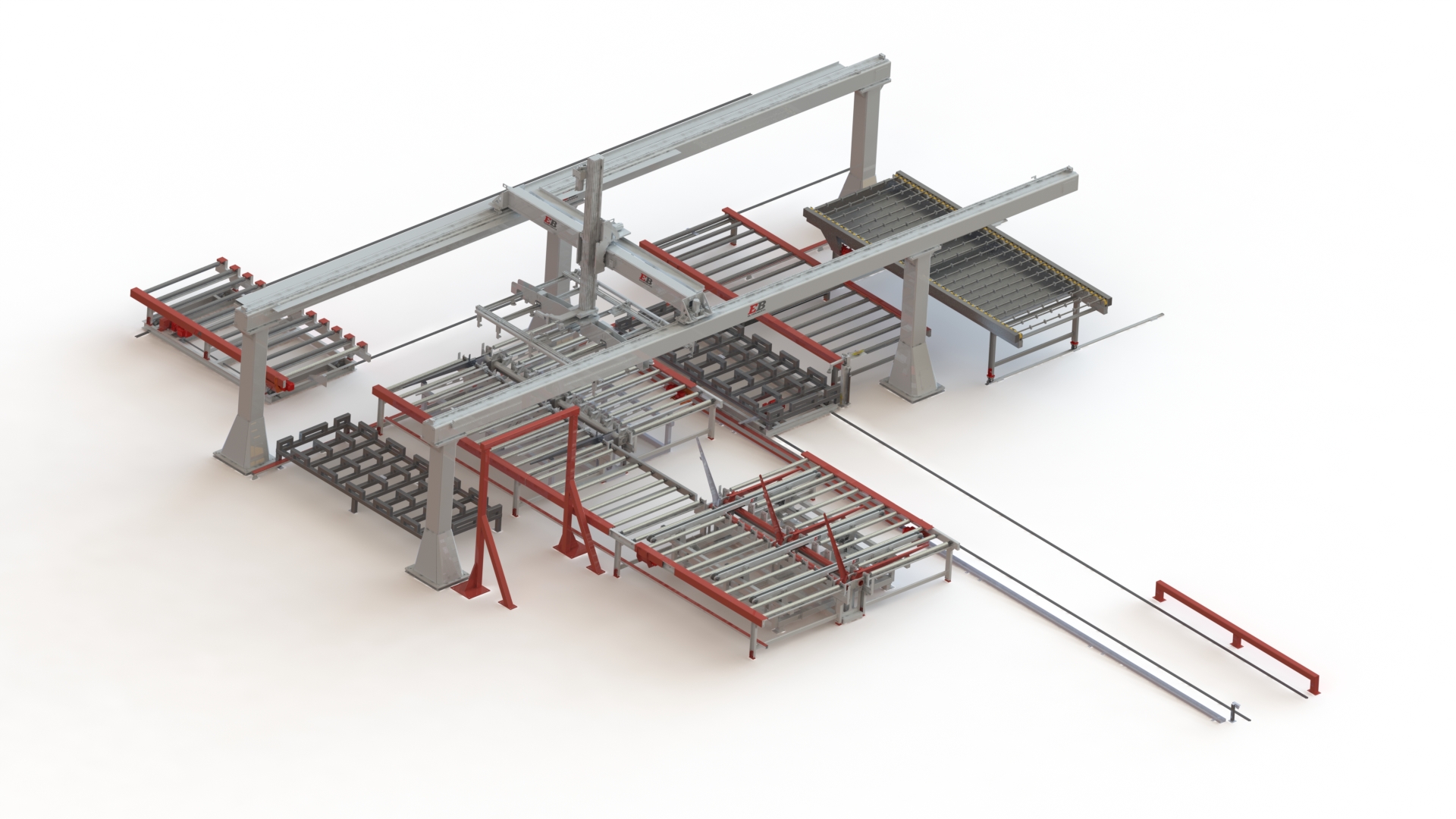

The solution can include multiple robots for handling components and finished products, a material feed system, multiple conveyors for moving materials, a perforation system, a glue applicator, a film unwinder, a press roller, and a flying saw (servo).

Three assembly types are possible:

- A rigid panel and a film

- Two or three rigid panels

- Two rigid panels and a film

The protection system consists of fencing and light curtains.

Standard Spécifications

- For components up to 5 m in length x 2 m in width

- Lifting capacity up to 250 kg

- Execution speed with a rate of up to one piece every 6 seconds

- Stacking precision based on the chosen options

- Non-standard capacities available

Avantages

- Easy integration

- Solve the labor shortage issue

- Increase production

- Improve the quality of manufactured products

- Enhance safety to eliminate accidents

- Flexible solution

- Adapted to Industry 4.0

- Turnkey project available

Options

- Interconnection with your existing system

- Automatic alignment

- Measurement system

- Automated quality control

- Turning system (front and back)