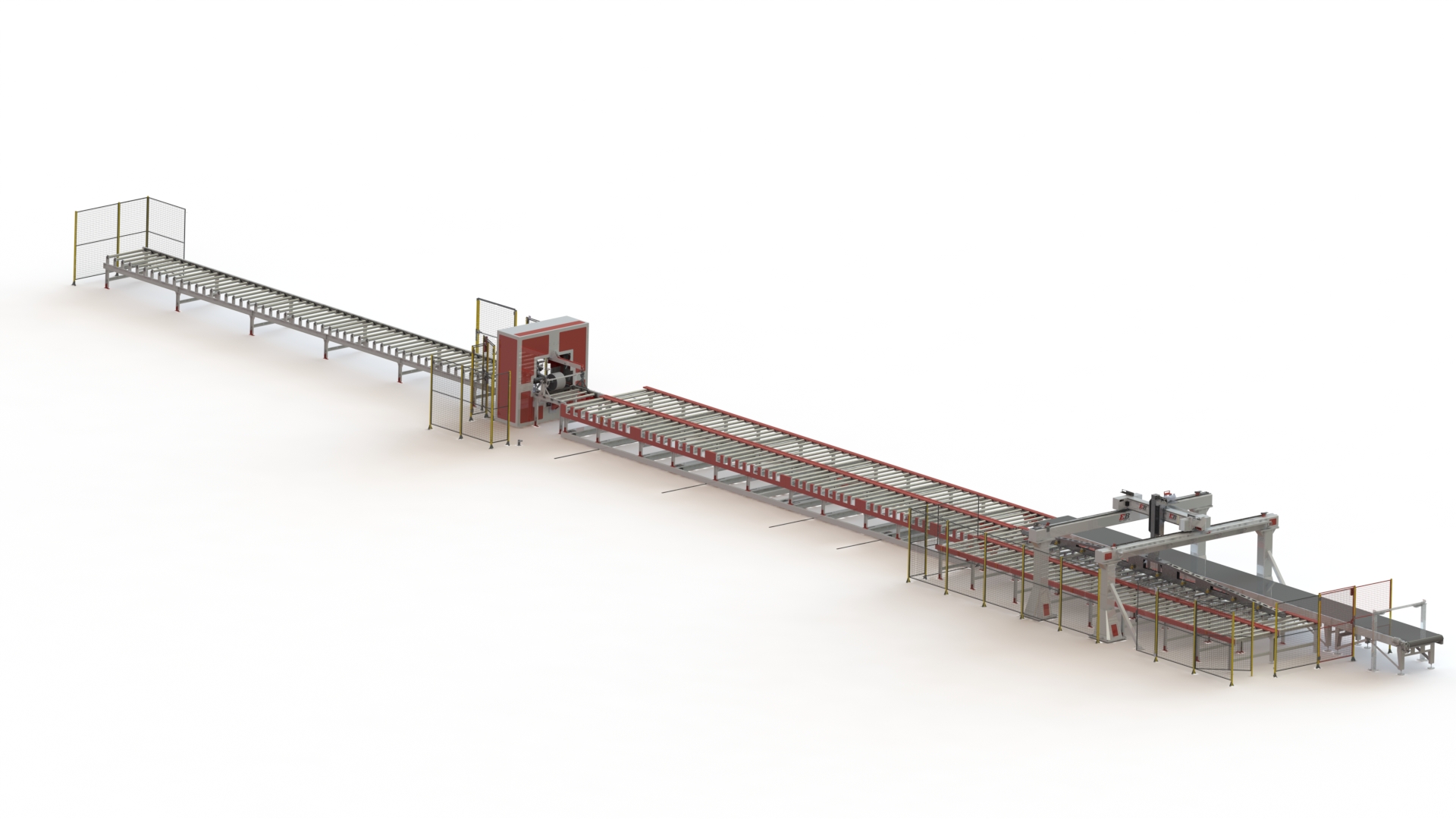

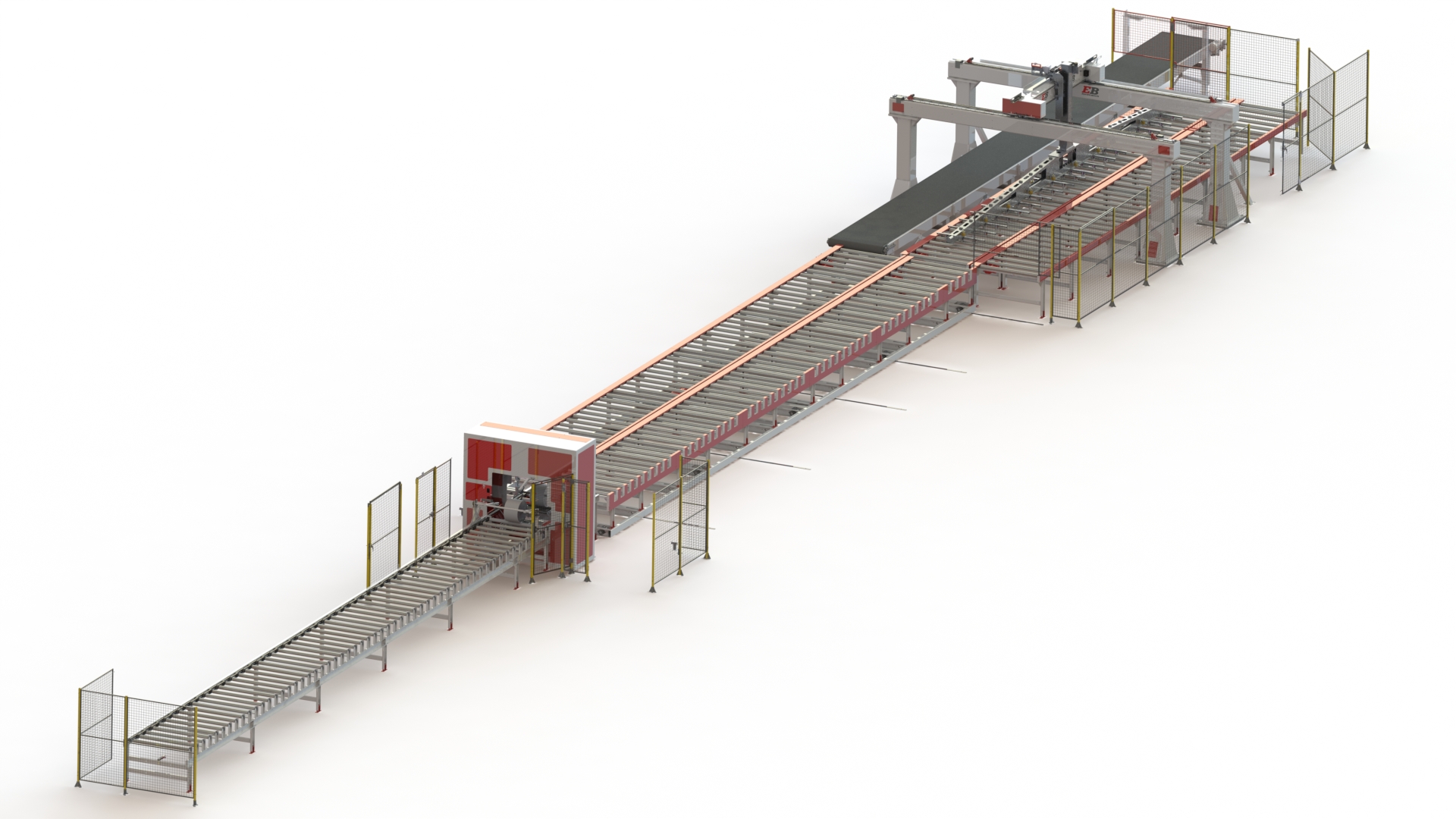

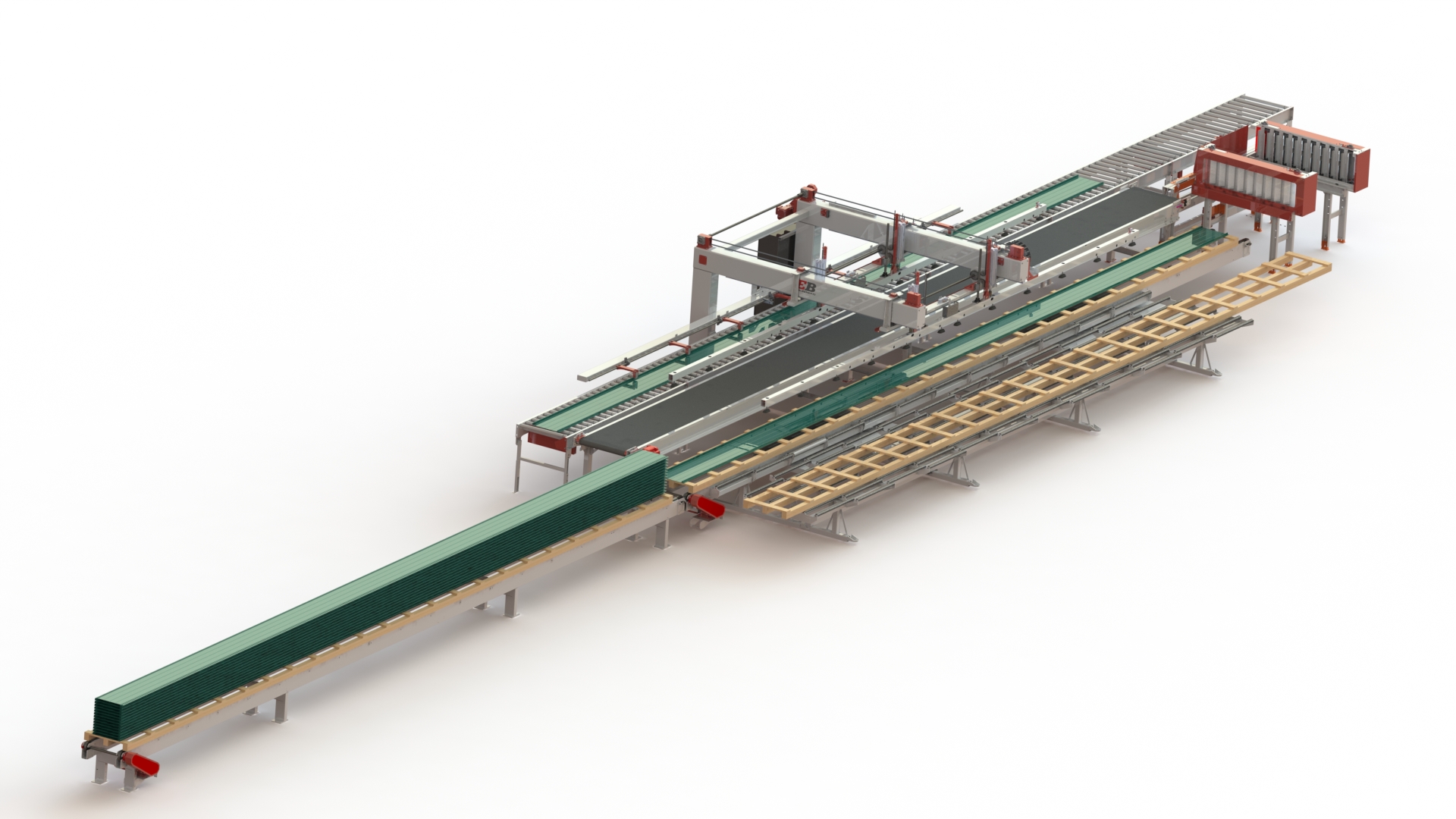

Stacking Sheets at Roll Former Exit

Description

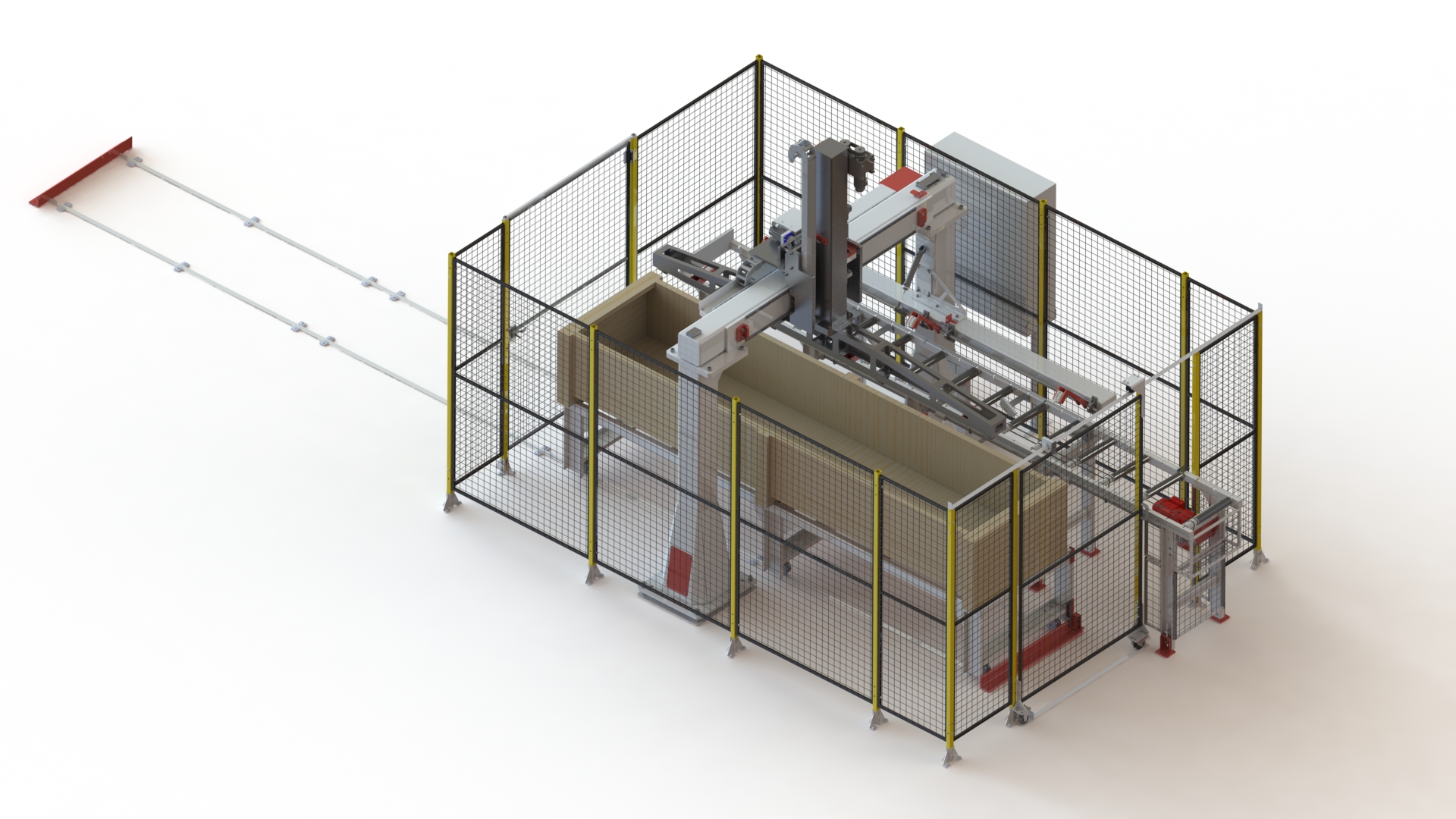

Handling sheets by the robot at the roll former exit to place them on a conveyor. Stacking can be done in a pyramid or stair pattern, regardless of the length. Non-compliant sheets can be placed on another conveyor in manual or automatic mode. Adding a camera ensures quality control.

The command, once completed, is automatically transferred to the packaging system for wrapping, and then moves onto the exit conveyor to be picked up by a forklift.

The solution includes an EAGLE series robot (for moving sheets) or FALCON series robot (for static sheets), conveyors, and a wrapper as needed.

The protection system consists of mesh and light curtains.

Standard Specifications

- For components from 30 cm to 15 m in length and up to 1 m in width

- Lifting capacity up to 250 kg

- Execution speed with a rate of up to one piece every 6 seconds

- Stacking precision based on the chosen options

- Non-standard capacities offered

Advantages

- Easy integration

- Solve the labor shortage issue

- Increase production

- Improve the quality of manufactured products

- Enhance safety to eliminate accidents

- Flexible solution

- Adapted to Industry 4.0

- Turnkey project available

Options

- Interconnection with your existing system

- Automatic alignment

- Measurement system

- Automated quality control

- Turning system (front and back)